Home » Shop » Robots & Cobots » Robots » ABB » ABB IRB 390 FlexPacker Delta Robot

ABB IRB 390 FlexPacker Delta Robot

Ultra-fast secondary packing with serious payload

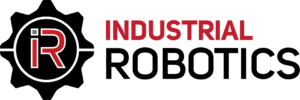

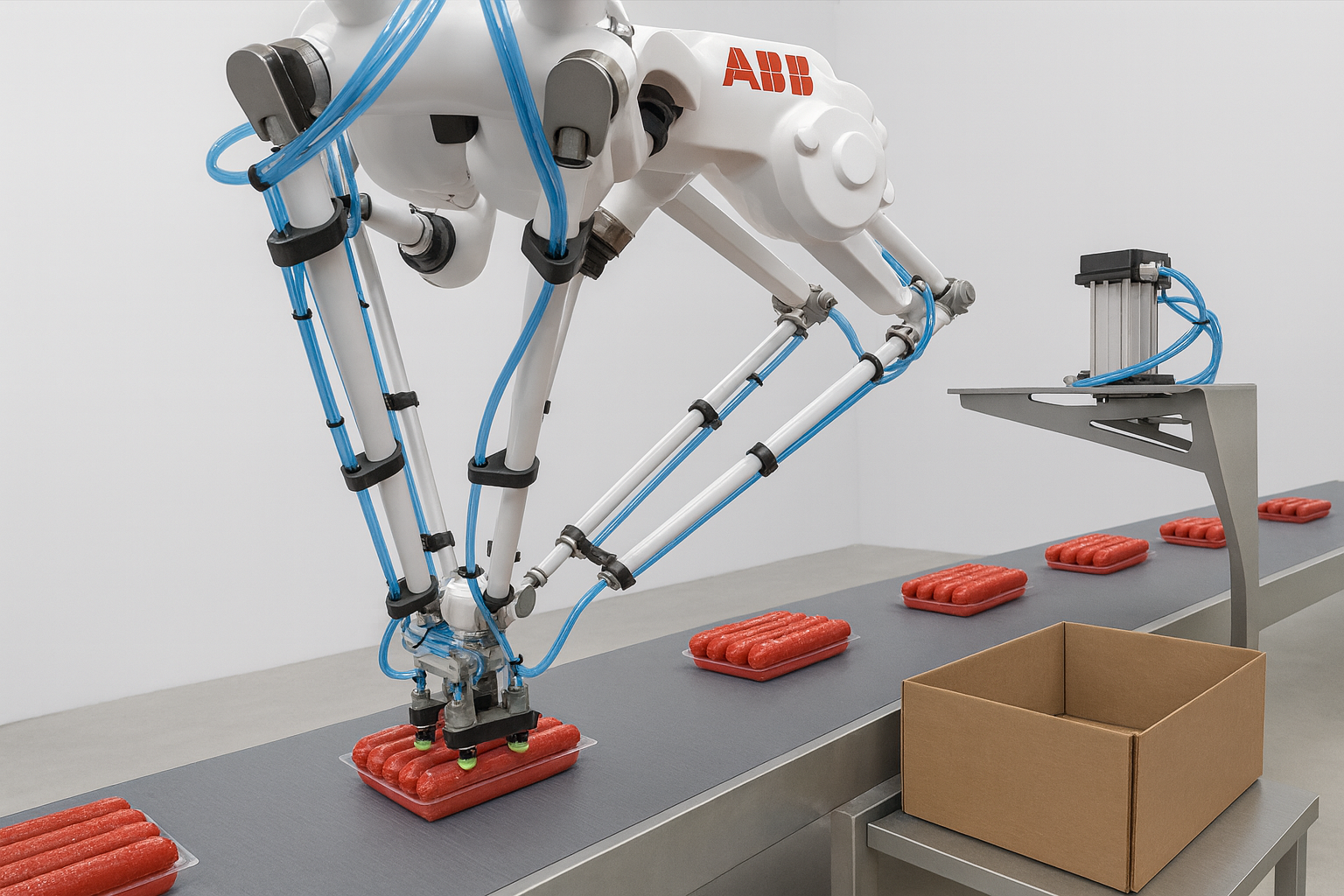

The ABB IRB 390 FlexPacker® is a high-speed, high-payload delta robot built to supercharge your packing line. With rapid cycle times, 4- or 5-axis flexibility, and the power to handle up to 15 kg, it delivers faster case loading, smarter orientation control, and consistently higher throughput. Designed for modern food, beverage and consumer-goods operations, the IRB 390 helps you boost productivity, reduce labour costs, and streamline every pick-and-pack task with unmatched efficiency.

Cant find what you’re looking for?

Fill out our quote form instead.

Description

The ABB IRB 390 FlexPacker is a high-performance delta robot designed for today’s high-mix, low-volume production lines. It supports payloads up to 15 kg and offers a large working envelope along with class-leading cycle times. It is purpose-built for secondary packing, SRP/RRP cases, and high-speed product handling in food, beverage, logistics, and consumer-goods plants.

Key Features & Advantages

- High payload delta design: Handles cartons, multipacks and trays up to 15 kg (4-axis variant) or 10 kg with the 5-axis version, enabling multiple product picks and fewer robots per line.

- More speed, more reach: Compared with the IRB 360-8/1130, the IRB 390 offers up to 35 % higher speed and 45 % larger working volume, boosting output per robot and giving your cell more layout options.

- Built for modern packaging lines: Designed to pick products from conveyors running at speeds up to 100 m/min, and then seamlessly transition to placing them into cases, crates, or trays with excellent path accuracy and consistent repeatability.

- Hygienic and food-grade: Uses NSF H1 food-grade lubricants and FDA-compliant materials, making it suitable for hygienically sensitive food and beverage applications.

- Integrated with ABB software: Works seamlessly with ABB PickMaster Twin and the IRB 360 FlexPicker, enabling vision-guided random-flow picking, digital-twin simulation and easy optimisation of multi-robot cells.

- 4- or 5-axis flexibility

- 4-axis, 15 kg – ideal where maximum payload and throughput are the priority.

- 5-axis, 10 kg – adds a tilting axis so the robot can stand products upright, angle packs and handle complex orientations without extra mechanisms, perfect for shelf-ready and retail-ready packaging.

Main Applications

The IRB 390 FlexPacker is ideal for:

- Shelf-Ready and Retail-Ready packaging (SRP/RRP)

- Loading cartons, cases, crates and trays with multipacks or mixed products

- Vertical orientation of juice cartons, bottles, pouches or wrapped goods

- High-speed sorting and collating for logistics and e-commerce fulfilment

- High-payload picking from flow-wrap or thermoform lines

Why Choose the IRB 390 from Industrial Robotics ?

Partnering with Industrial Robotics for your IRB 390 FlexPacker cell gives you:

- Application engineering – we model payloads, reach, cycle times and packaging formats to confirm the IRB 390 is the right fit.

- Turnkey line integration – conveyors, vision, case packers, end-of-line equipment and safety all engineered as one system.

- Custom tooling – bespoke grippers for cartons, bags, bottles, pouches or mixed packs, designed and built locally.

- Compliance & safety – design and documentation aligned with AS/NZS standards for machinery and functional safety.

- Local service & support – commissioning, training, remote support and preventative maintenance from our Australian team.

Ready to boost your packing line?

For more information on this product click here for Product Specification and Datasheet

Talk to us about deploying the ABB IRB 390 FlexPacker in your business. Contact us now to discuss your project. Alternatively, submit a Request a Quote via our website. Include your product dimensions, packaging style, throughput, and available footprint.

Contact Industrial Robotics today!