Home » Shop » Solutions » Machine Tending » Injection Molding Machine Tending Package

Injection Molding Machine Tending Package

The proposed solution is a UR12e or UR20 with insulation plate that can be installed on a welding table.

The Package includes:

- UR Collaborative Robot

- Euromap Injection Moulding

- Table

- Workbench

- Gripper

- Wrist Camera

- Floor Locking Pin

- QA Camera

- IP Camera Remote Monitoring

- Complimentary Camera support and VPN server fee

- Light and Sound Signal Tower

- Training

- Commissioning

- Optional: UR Care Package offering is comprised of essential resources needed for a successful deployment and continuous operation of your robot.

Estimated development time for the solution is: 3 months from order, including robot delivery time.

Cant find what you’re looking for?

Fill out our quote form instead.

Description

The process of operating and maintaining injection molding machines, which are used to produce plastic parts and products through the injection molding process. We have recommended a collaborative robot UR12e or UR20 with this package. This solution will allow you to enter the Industry standards. It will provide you with substantial range of benefits for your company, including: reduce labor costs, increase productivity, increase safety, reduce RSI risks, improve product quality, reduce human error, streamline the process, reduce overall product cost, among other advantages.

Universal Robot UR12e or UR20

These high-quality, industrial-grade robots can operate for extended periods with minimal servicing required. The standard order includes a robotic arm, a control box, a teach pendant, a power cable, and a cable connecting the arm to the control box, along with the necessary documentation. Additionally, the UR cobot comes with a service package for peace of mind. Information about this service package Click Here

For more information about the UR12e Robot: Click Here

For more information about the UR20 Robot: Click Here

Tables

Option 1: SDC-5E Portable Deluxe Service Tool Cart

The SDC-5E Portable Deluxe Service Tool Cart is the ultimate tool storage solution. It features five spacious drawers with smooth ball bearing slides and safety quick-access finger latches to prevent accidental openings during transport.

For more information on this product Click Here

Option 2: Daytona DMB1100 Heavy-Duty Mobile Workbench

The Daytona DMB1100 Heavy-Duty Mobile Workbench is an ideal solution for all your automation needs, offering a sturdy and spacious workspace that can handle even the most demanding tasks.

For more information on this product Click Here

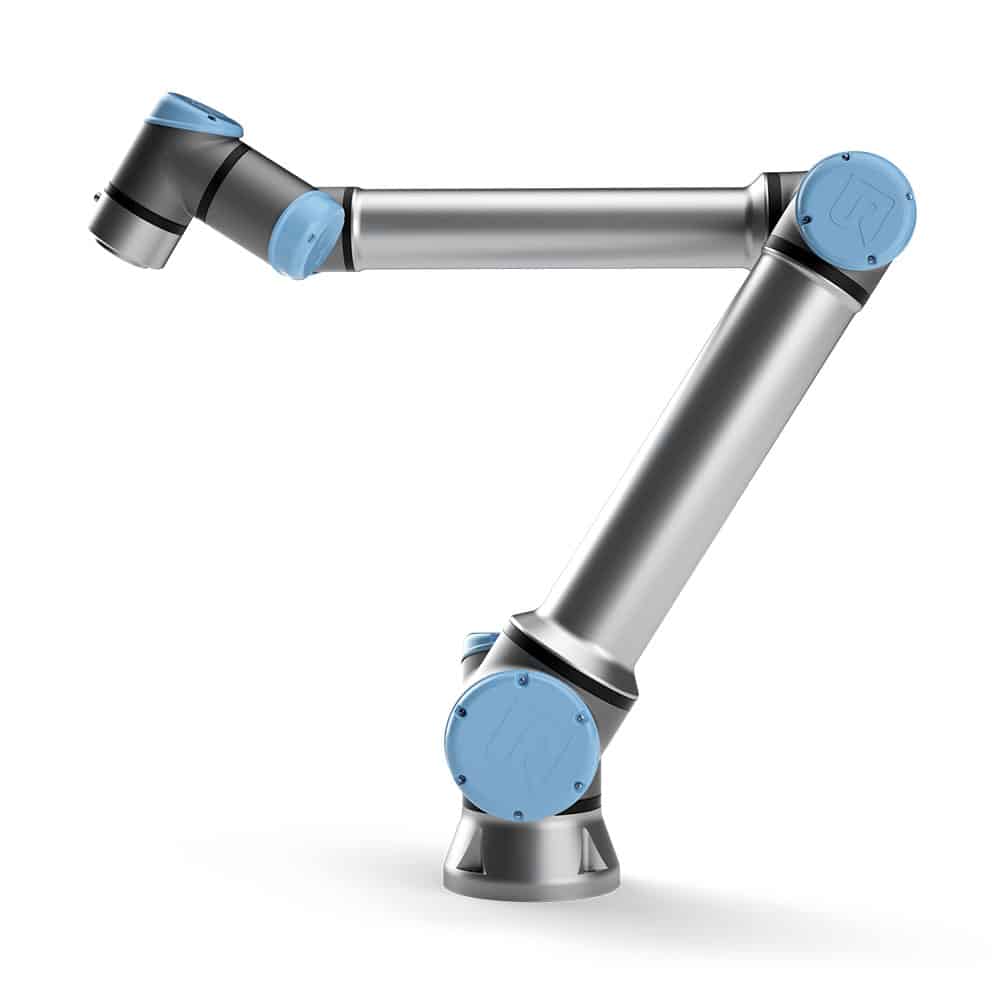

Euromap Injection Moulding

The e-Series Injection Molding Machine Interface (IMMI) option provides standardized connectivity between an e-Series robot and injection molding machinery. The IMMI is a separately orderable option for all e-Series robots and supports both EUROMAP 67 and SPI AN-146.

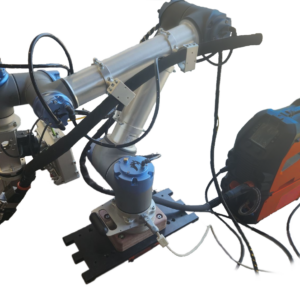

Gripper

The gripper will be designed to perform the following actions:

- Pick part to be over-moulded

- Open mould door

- Pick previous part in the mould

- Place new part in the mould

- Close the door

- Allow mould to close

- Place the part on the finish pile to be inspected

Those are the base components we will use to design your gripper from FESTO:

- 2 Parallel gripers DHPS-6A

- 2 Guided drive DFM-12-30-P-A-GF to move the gripper forward and backward

- Slot Cover

- Proximity Sensor

The surrounding structure will be custom designed and built to match your gripper’s exact requirements. The gripper will operate via pneumatic actuation, requiring an airline at the robot table for proper functionality.

Wrist Camera

The Robotiq Wrist Camera is a compact and user-friendly vision system, tailor-made for seamless integration with Universal Robots. It streamlines machine tending, pick-and-place, and assembly operations, offering precise performance and simple programming.

For more information on this product Click Here

Floor Locking Pin

Our custom floor locks securely position your robotics table in the exact spot needed for the robotics program to run properly.

QA Camera Package

The FH7 OMRON camera is easy to program using Windows PC software, offering a seamless setup. Mounted on a stand at the service table, it is triggered by the robot when a part is picked up and positioned for inspection. The camera captures multiple angles to verify whether the overmould meets QA criteria. If the part fails, it’s placed in a reject pile or box; if it passes, it’s added to the good parts pile. This efficient process ensures accurate quality control and automated sorting.

For more information on this product Click Here

IP Camera Remote Monitoring & Support

Incorporating IP Camera Remote Monitoring into your robotic automation package is crucial for maximizing efficiency and security. This advanced surveillance solution allows you to monitor operations in real-time, ensuring that your robotic systems are performing optimally.

With this addition you can contact us during working hours if you require any support on your robotics system. We can assist you remotely as we will have a visual from the PTZ IP camera and will be able to access the robot control box as as well as the QA camera.

Support and VPN server fee is complimentary for the first year.

Optional Extra: Light and sound Signal Tower

The package features an OMRON quality control (QA) camera, remote support through a VPN router, and a NESS PTZ camera for advanced monitoring and performance. It also allows you to connect up to three lights and a buzzer, delivering clear alerts when the robot stops or the pile is empty. These alarms ensure you’re always informed, enabling quick responses for smooth, efficient operations.

For more information on this product Click Here

For more information or to request a quote, please send us an enquiry. We’re here to help you achieve your automation goals with tailored business solutions designed for success.

Additional information

| Collaborative Robot | UR10e or UR20 |

|---|---|

| UR Care | UR Care Package |