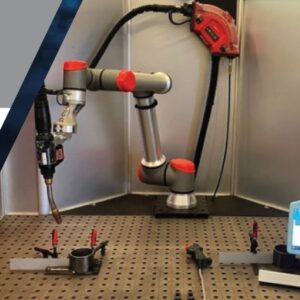

WeCobot Welding Solution with Fronius Welder

Smarter welding starts with one hand — teach, weld, repeat.

Double your welding workforce without doubling your staff. Boost your welding capacity with the WeCobot Welding Solution – a safe, mobile cobot system that integrates seamlessly with Universal Robots and the Fronius welding unit.

This innovative package pairs collaborative robots with world-class welding technology to deliver safer, faster, and easier automation. With simple one-hand learning, welders can guide and teach the robot by hand — no programming required.

Designed for quick learning, effortless integration, and maximum productivity, the WeCobot Welding Solution is the smarter way to weld.

Cant find what you’re looking for?

Fill out our quote form instead.

Description

The WeCobot Welding Solution with Fronius is a turnkey system for automating welding tasks alongside human operators. Designed for simplicity and safety, it offers plug-and-play setup, intuitive teaching tools, and compatibility with industry-leading Fronius power sources.

Why Choose the WeCobot Welding Solution with Fronius Welder?

Quick to Learn

- Innovative interface to fine tune options.

- Uses familiar manual welding equipment.

- Tutorials and remote support included.

Hand-teaching with ONE – With the WeCobot ONE system, welders can program by hand instead of code.

- FreeDrive Mode: Hold the black button on the ONE ring to activate FreeDrive and manually guide the robot into position.

- Blue Button Controls: Use the blue button to save each pose, toggle between Air and Weld mode, or switch between linear and circular motion when teaching.

- Single-Button Teach: The system is built for welders — simply guide the torch to define a path, no programming required.

- Repeat Weld: After teaching one weld path, automatically repeat it across multiple parts or fixtures for consistent results.

- Plug & Play Simplicity: Designed for ease of use — “if you can weld and use a smartphone, you can run it.”

Safety & Compliance – Highlight international safety standards: Built to meet and exceed global collaborative robot safety standards, the system allows open workspaces without fencing — integrating acoustic and visual safety signals for operator confidence.

🧠 How It Works

Describe a quick-start workflow:

- Unbox and connect using plug-and-play components.

- Launch the ONE software app from the UR interface.

- Use the on-arm buttons or FreeDrive ring to guide the robot.

- Save each weld point and select process parameters.

- Start automated welding with repeatable precision.

🔶 Fronius-Cobot Solution

Compatible Welding Sources:

- Fronius Transsteel, Transsteel Pulse, TPS/i

- Welding Processes: Standard, Pulse (PMC), LSC, CMT MIG/MAG

Welding Output:

- 320A / 400A / 500A / 600A

WeCobot Kit Includes:

- Process control station

- Fronius robot torch MTB 500i

- Signaling ring

- Welding machine interface

- WeCobot ONE software (1-year subscription, remote support & updates)

UR Cobot Integration

- Compatible with UR12e and UR7e

- Robot reach: up to 1300 mm

- Payload capacity: up to 33.5 kg

- 6-axis control with absolute encoders

- ±360° working area orientation

- Repeatability accuracy: ±0.05 mm

Key Benefits at a Glance

- Plug & Play setup: minimal downtime for integration.

- Enhanced productivity: extend your welding department without fencing or major reconfiguration.

- Future-ready software: continuous updates and remote support with WeCobot ONE

- Quick learning curve — ideal for skilled welders, not programmers.

Contact us today for any enquiries or to request a quote!