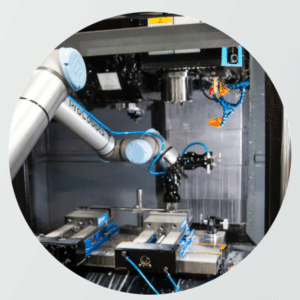

Blue Dragon FRAMEwork + UR10e

-

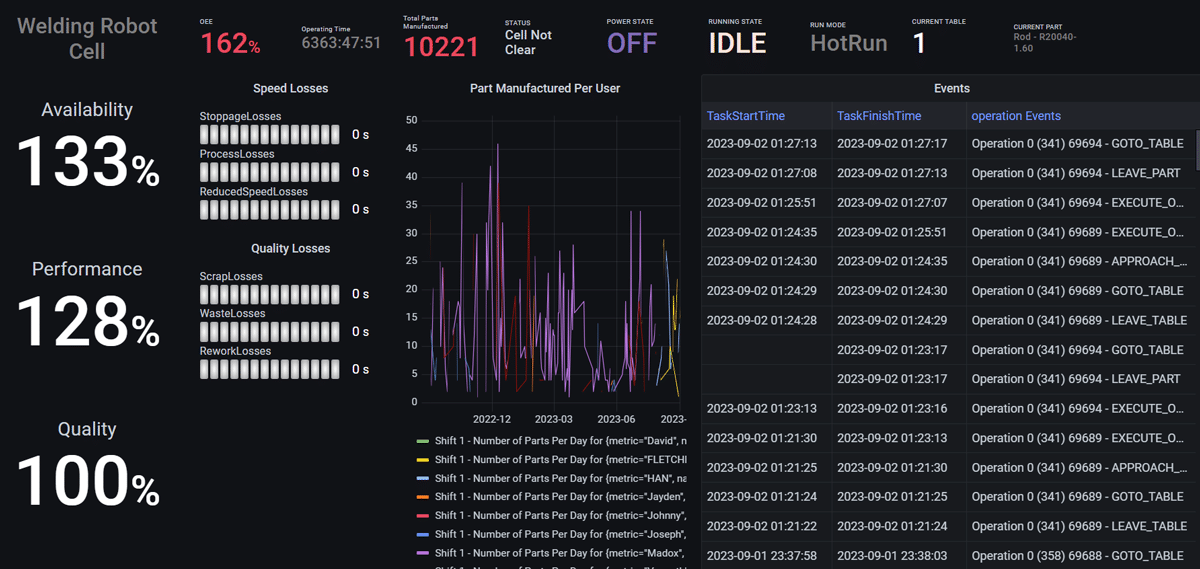

Machine Vision Upgrade for Industrial Robotic Cells

-

Compatible with Universal Robots, Kuka, ABB

-

Scans parts and automatically saves CAD files

-

Recognises parts, features and associated robotic operations

-

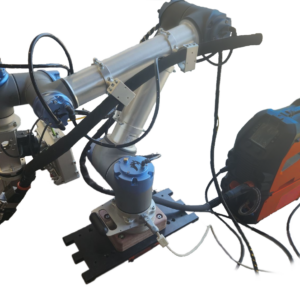

Currently optimised for Welding & Deburring

-

Sanding & Polishing support coming soon

Cant find what you’re looking for?

Fill out our quote form instead.

Description

Why choose Blue Dragon?

-

Flexible – great for small runs, rapid prototyping and variable orders

-

Self Programming – avoid cost, risk and delay relying on 3rd Party robotics programmers

-

Real world tolerances for part variance & deformation – avoids collision with imperfect parts

-

No jigs required – simply place parts on the table

-

Business Intelligence Dashboard – see production and quality statistics in real time

-

Faster batch times + higher utilisation = faster ROI

UNLIMITED APPLICATIONS

- Fabrication, Machining, Finishing

- Full operation with lower skilled staff

- Training methods: CAD, hand train, marker pen, scan to mesh features

- No requirement for part positioning

- Quality control analysis

- Local & Cloud based storage

- Real time data accessable online

- Generates factory level data or machine production metric reports

- International Patent Pending

PCT/AU2023/050277

3D MODELLING AND ROBOTIC TOOL SYSTEM AND METHOD

SPECIFICATIONS

- < 0.5mm accuracy

- No jig required

- Scan to mesh / part mesh from CAD

- Process edges and surfaces

- Fit industrial & collaborative robots

- Digital Twin simulator

Related products

Looking for a quote?