Plasma Cutting Solution

Elevate your cutting operations with our Plasma Cutting Solution – the perfect combination of precision, efficiency, and versatility.

This advanced system uses high-velocity plasma to deliver clean, accurate cuts through steel, aluminum, and copper, making it ideal for industries like manufacturing, construction, and automotive.

Powered by cutting-edge automation, our solution ensures consistent, high-quality results, boosting productivity and streamlining your workflow.

Take your operations to the next level with technology designed for success!

Cant find what you’re looking for?

Fill out our quote form instead.

Description

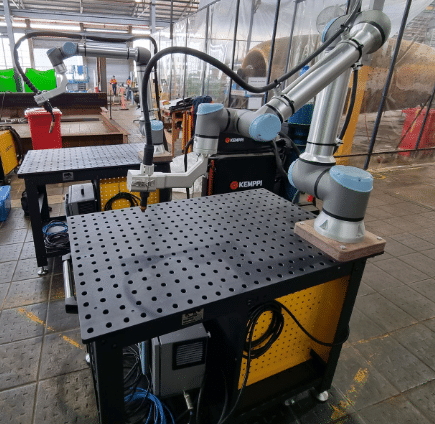

The Solution

Plasma cutting is a precise and efficient method for cutting electrically conductive metals such as steel, aluminum, and copper. It uses a high-velocity stream of ionized gas (plasma) to melt the material, while a powerful gas flow blows away the molten metal, creating clean and accurate cuts. This process is ideal for industries requiring detailed and high-speed cutting, including manufacturing, construction, and automotive applications.

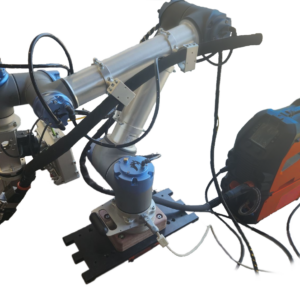

Take your cutting operations to the next level with our fully integrated Robotic Plasma Cutting Solution, designed to deliver precision, efficiency, and versatility. Leveraging advanced automation and cutting-edge technology, this system is the perfect choice for industries looking to enhance productivity while ensuring consistent, high-quality results.

Key Components of the Solution

Universal Robot (UR): At the heart of the system is the reliable and easy-to-program Universal Robot, which ensures smooth and accurate robotic movements. Its flexibility makes it ideal for plasma cutting applications across various materials and shapes.

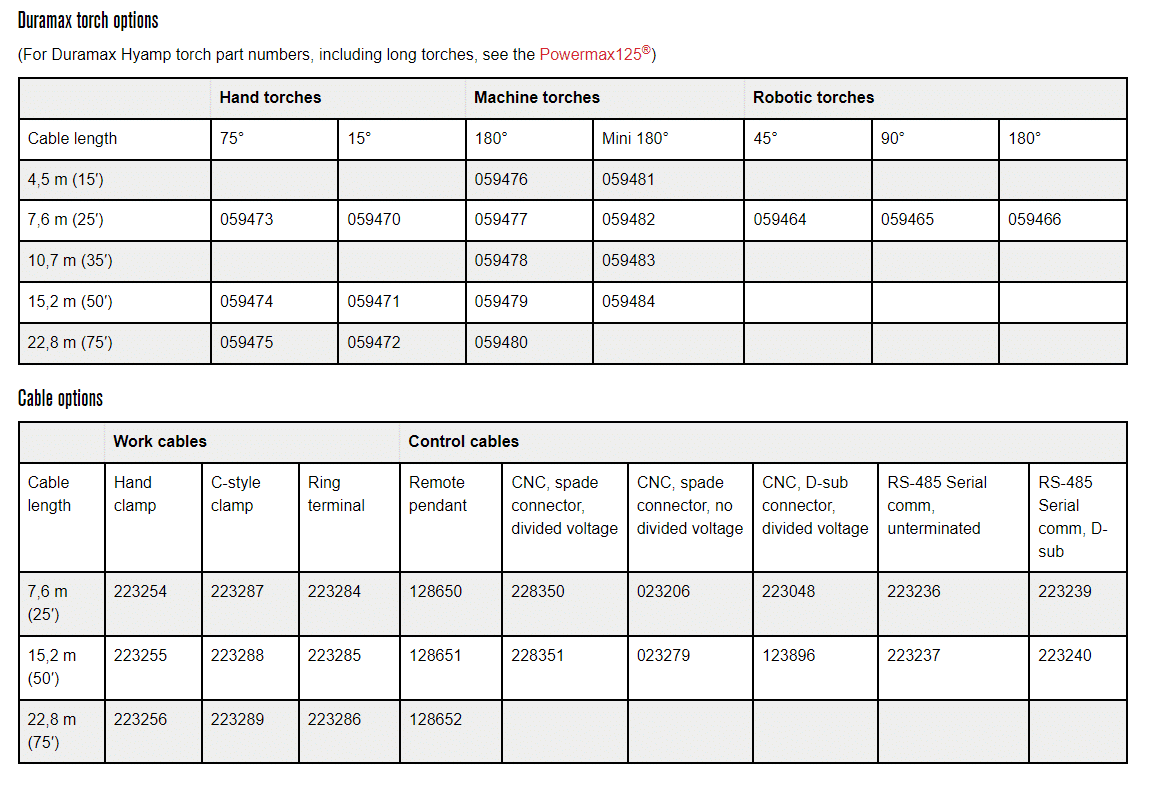

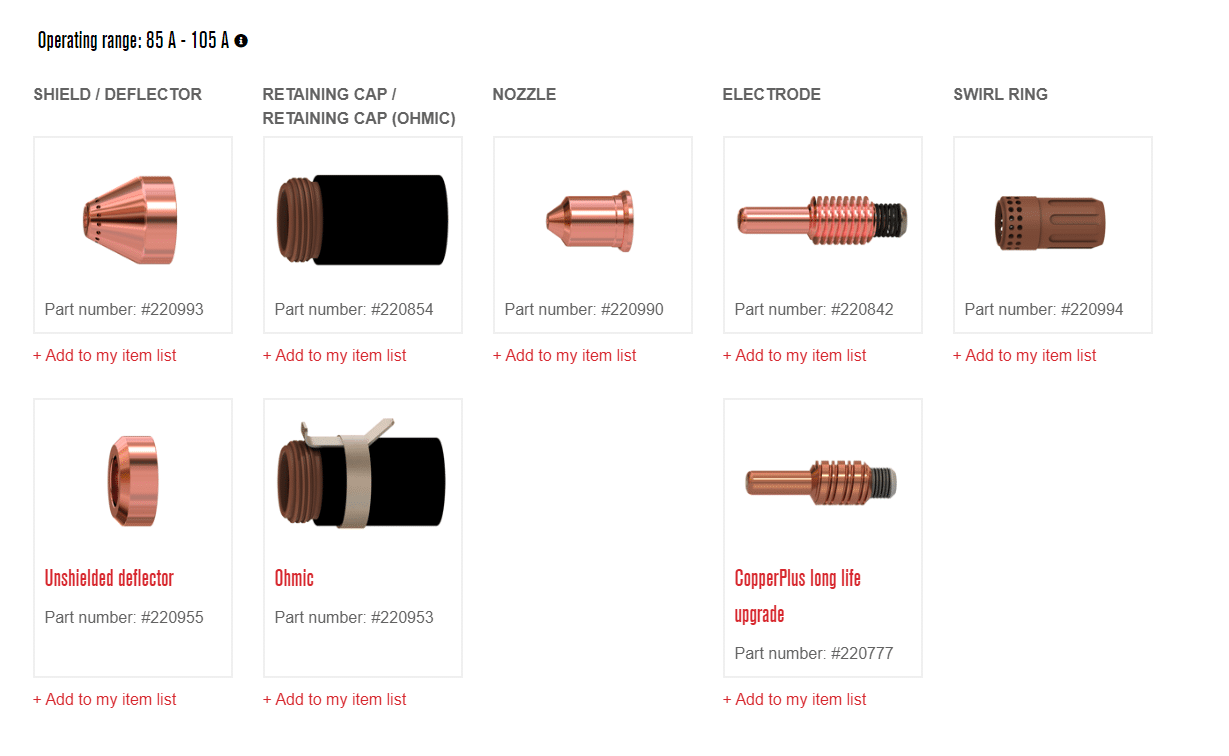

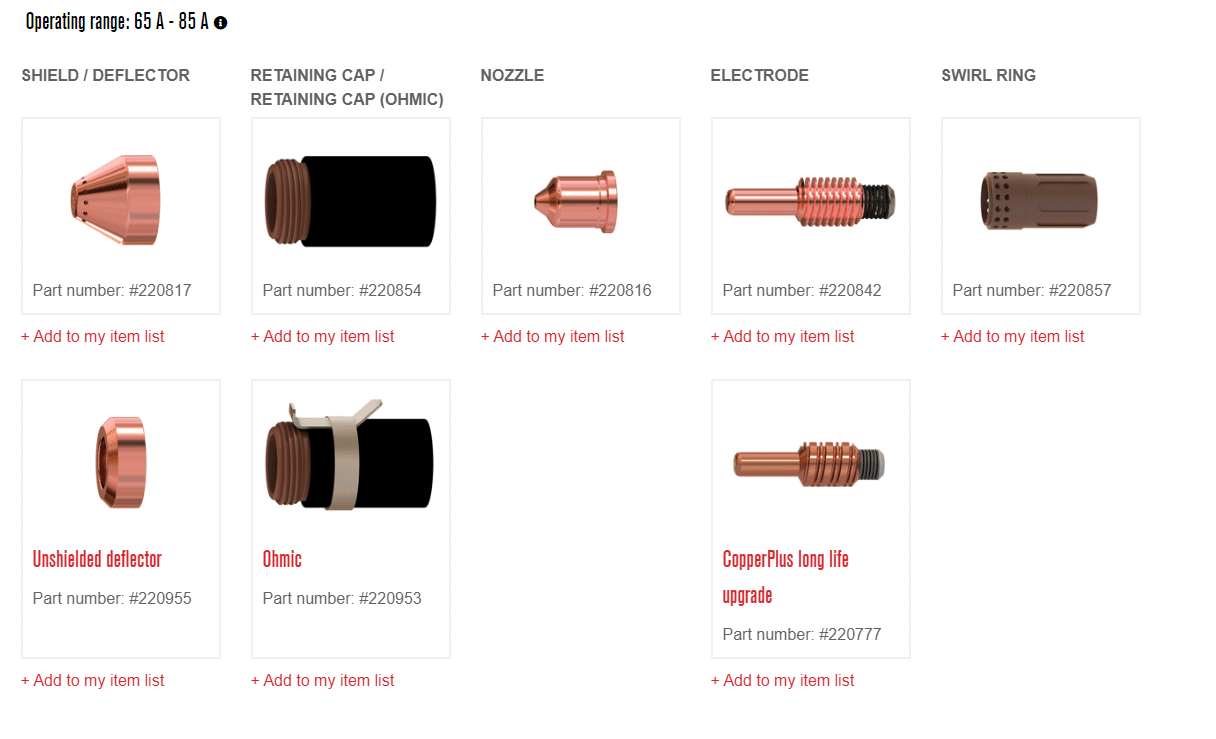

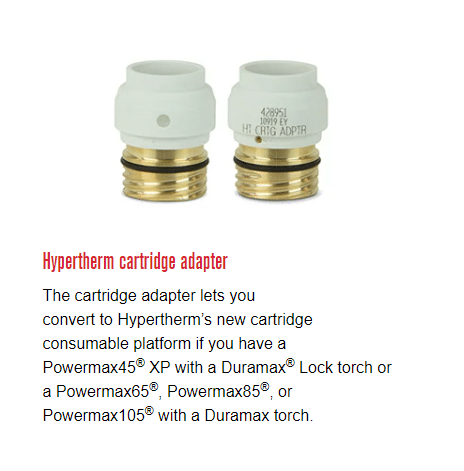

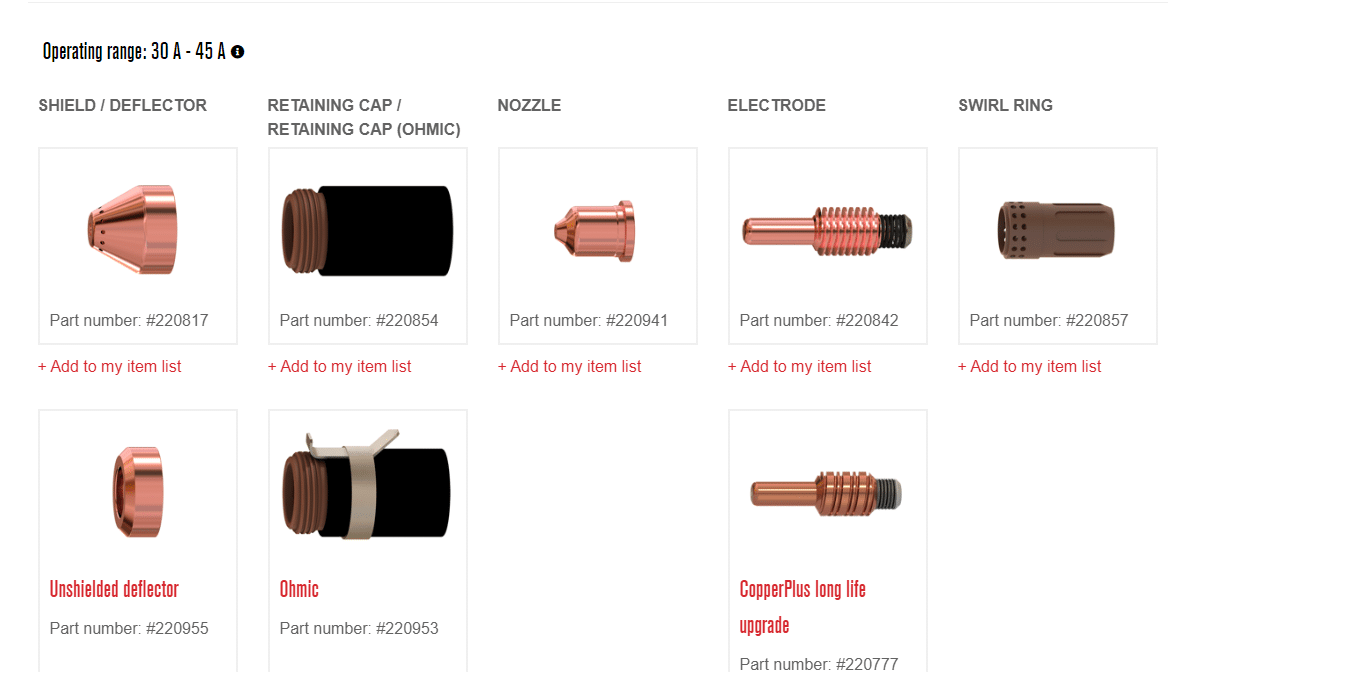

PowerMax 105 Plasma Cutting Station: The PowerMax 105 is a state-of-the-art plasma cutting station, renowned for its power, efficiency, and reliability. It handles a wide range of cutting applications, offering high-speed performance and excellent cut quality for various material thicknesses.

Accessories for Enhanced Functionality: Our solution comes with a complete set of accessories to optimize the plasma cutting process, ensuring seamless integration and efficient operation.

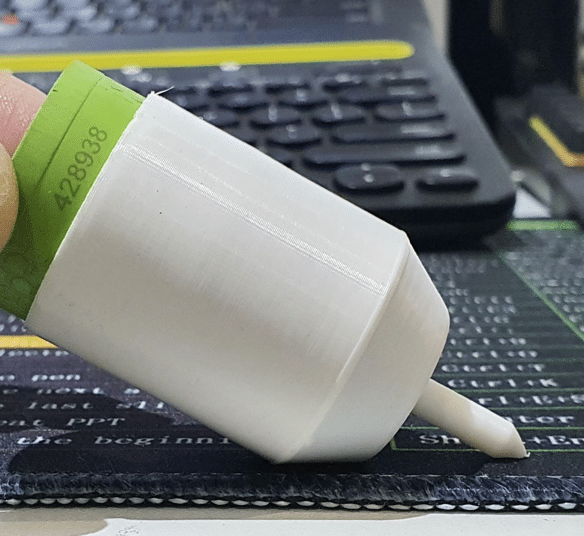

TCP Calibration Tip: The Tool Center Point (TCP) Calibration Tip guarantees precise alignment and calibration, ensuring the robot maintains accuracy throughout the cutting process. This feature reduces errors and minimizes material waste.

Plasma Torch: The robust plasma torch delivers high-velocity cutting performance, ensuring clean, precise cuts through materials like steel, aluminum, and copper. Its ergonomic design and durability make it ideal for demanding industrial environments.

Why Choose Our Robotic Plasma Cutting Solution?

- Precision and Consistency: Achieve perfect cuts every time with advanced robotics and precise calibration tools.

- Increased Productivity: Automate repetitive cutting tasks to save time and reduce labor costs.

- Versatility: Handle diverse materials and complex shapes effortlessly.

- Ease of Use: Simplified programming and integration for quick setup and operation.

- Durability: Built with high-quality components designed to perform in demanding environments.

Applications

Our Plasma Cutting Solution is ideal for:

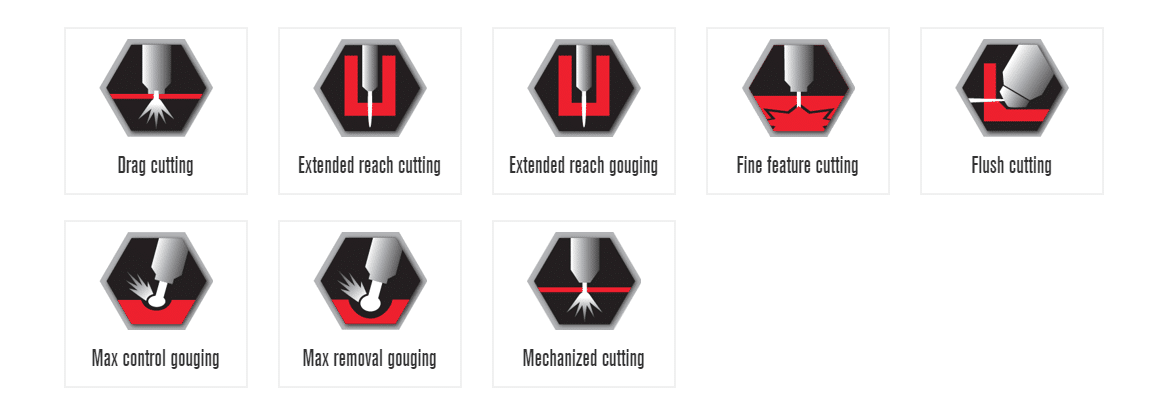

- Drag cutting

- Extended reach cutting

- Fine Feather cutting

- Flush cutting

- Max control gouging

- Max removal gouging

- Mechanized cutting

Ready to Transform Your Cutting Process? Discover how our Robotic Plasma Cutting Solution can streamline your workflow and deliver unparalleled results.

For more information or to request a quote, contact us today! Let us help you achieve your goals with customised business solutions designed for success.