Home » Shop » Robots & Cobots » Robots » Kuka » KUKA KR Delta Robots

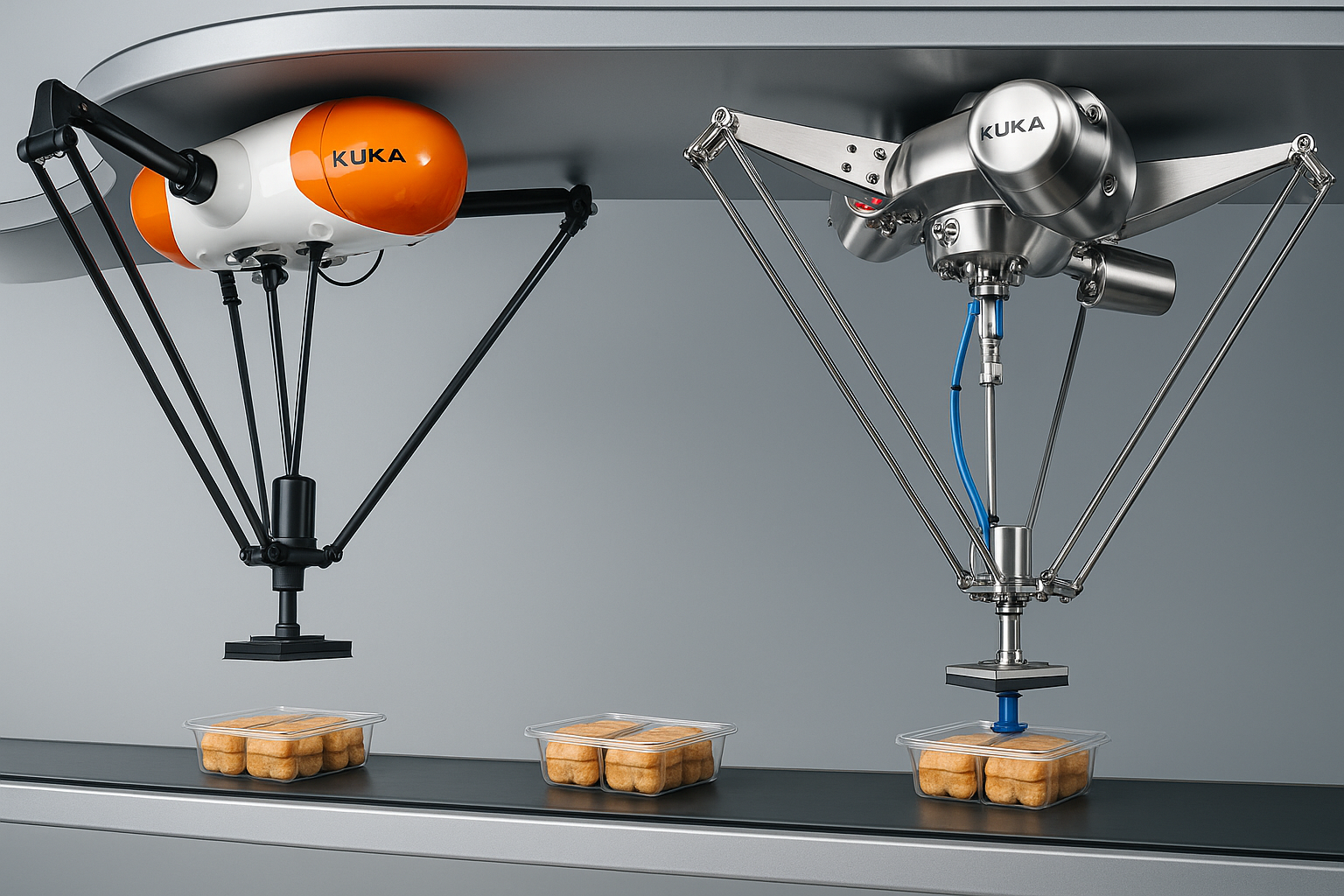

KUKA KR Delta Robots

Lightning-fast. Ultra-precise. Built for hygienic production.

The KR DELTA series delivers blistering pick-and-place speeds with cycle times down to 0.32 seconds and payloads up to 6 kg. Designed in stainless steel or carbon fibre, these robots excel in food, pharmaceutical and electronics environments where cleanliness and accuracy are essential.

Cant find what you’re looking for?

Fill out our quote form instead.

Description

Experience ultra-fast, ultra-accurate pick-and-place performance with the KR DELTA series. Built for high-speed production, these robots deliver cycle times as low as 0.32 seconds while maintaining exceptional precision.

With payloads up to 6 kg and a choice of stainless-steel or carbon-fiber construction, they’re engineered for environments where hygiene and reliability are critical—whether handling fresh food, pharmaceuticals, or delicate electronic components.

A wide working envelope and impressive flexibility make the KR DELTA a powerful solution for automation across many industries.

Engineered for outstanding cost-efficiency, KR DELTA robots keep operating expenses low with self-lubricating joints, sealed drive systems, and motors mounted directly at the base for easier maintenance. Paired with the compact, energy-efficient KR C5 micro controller, they offer dependable performance, minimal footprint, and excellent long-term value.

Key Features

- 4 axes delta-kinematics for extremely fast cycle times and low inertia.

- Rated payload 3 kg with ability to go up to 6 kg in select cases.

- Maximum reach / diameter of 1200 mm — large work envelope for a delta type.

- Outstanding repeatability: ± 0.05 mm per ISO 9283 for high-precision tasks.

- Compact footprint Ø350 mm (approx), ideal for space-constrained cells.

- Robust protection rating IP67 for the robot body; hygienic variants available for food / pharma applications.

- Modern controller: KUKA KR C5 micro — compact, high-performance automation platform with cloud/IoT readiness.

- Suitable for ceiling-mount or inverted mounting, freeing valuable floor space.

Applications

- High-speed pick & place of bottles, trays, blister packs and packaged goods.

- Sorting and feeding parts in food & beverage lines (snacks, confectionery), pharmaceutical vials or syringes.

- Machine tending/unloading and inserting small part components.

- Packaging, palletising or depalletising tasks where cycle time and space are critical.

Why choose the KR Delta Robots for you automation cell?

- Blistering speed for throughput – Its delta parallel-arm design enables one of the fastest action cycles in its class.

- Large reach with minimal footprint – 1200 mm diameter work-envelope with compact ceiling-mount design means you save valuable floor space.

- High precision & repeatability – Ideal for demanding pick-&-place accuracy, insertion and packaging tasks.

- Hygienic & industrial robustness – The IP67 (and in hygienic version IP69K) rating plus stainless materials make it suitable for food, pharma or clean environments.

- Modern control & integration readiness – With the KR C5 micro controller you get future-proof connectivity (IIoT/Industry 4.0) plus tight integration into conveyors, vision, networks.

- Australian support – As your trusted automation partner, Industrial Robotics can supply, integrate, commission and service the KR 3 D1200 locally.

What you receive in the box / Standard Delivery

- KUKA KR 3 D1200 robot (4-axes) – specified model & reach.

- Controller cabinet (KR C5) with power, safety circuitry, fieldbus/Ethernet communication.

- Teach pendant and basic programming suite (KUKA interface).

- Basic cable set (robot to controller, safety circuit, power).

- Commissioning assistance / technical support from Industrial Robotics.

- Optional integration services — vision system, conveyor interface, custom end-effector design, safety guarding (quoted separately).

Integration & Services

Industrial Robotics offers full turnkey services when deploying the KR 3 D1200:

- Feasibility & layout study — ensuring optimum footprint, reach, cycle time and cell design.

- Programming & commissioning — onsite in Australia, including integration with conveyors, vision systems, HMI.

- Safety certification — ensuring compliance with local standards (e.g. AS/NZS 4024).

- Maintenance & spare-parts service — to maximise uptime across the asset’s lifetime.

- Upgrade & retrofit paths — should your line change, the KR 3 D1200 is a flexible asset ready for new parts or packaging sizes.

For more information

More more information on these products Click Here

Register and gain access to more detailed information about the product, downloads and much more! You can find exclusive content when logged in to myKUKA: Kuka

Ready to super-charge your production line with the KR 3 D1200?

“Request a quote” — please specify your part cycle time, payload, reach requirements and production rate for a tailored solution.

Contact Industrial Robotics today!

Additional information

| Total Load | 3kg |

|---|---|

| Reach | 1200mm |

| Number of Axes | 4 |

| Protection Rating | IP 67, IP 69K |

| Mounting positions | Ceiling |

| Construction type | Standard |

| Version environment | Standard & Hygenic machine |