Home » Shop » Welding Products » Welders » Robotic Welders » EWM Robotic MIG/MAG Welders

EWM Robotic MIG/MAG Welders

The next-generation welding system is specifically designed for superior performance and flexibility.

Its modular design not only allows for easy upgrades and system add-ons but also offers the flexibility for future expansion. Furthermore, the intuitive graphical interface ensures user-friendly operation, making it simple to navigate and control.

In addition to these features, the system boasts improved weld properties, optimized operator-machine communication, and a robust construction. As a result, it is built to meet the demands of the future of welding.

Cant find what you’re looking for?

Fill out our quote form instead.

Description

Automated MIG/MAG multi-process robotic welding machines

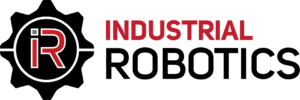

Step into the future of automated welding with the Titan XQR Puls, the pinnacle of advanced power source innovation. Building on the legacy of the Phoenix Puls and Alpha Q Puls, this flagship system sets a new benchmark with cutting-edge RCC inverter technology and enhanced XQ welding processes.

Designed for both gas and water-cooled setups, the Titan XQR Puls adapts seamlessly to torch-changing systems, offering unparalleled flexibility. Its impressive range, powered by up to three drives in series (depending on configuration), ensures reliable performance over extended distances.

Whether you’re working with different materials or varying thicknesses, the Titan XQR Puls delivers precision-engineered weld seams, every time.

Control Expert XQR 2.0

Welding program sequence: Simple adjustment of all welding parameters in the program sequence

- JOB window – Simple JOB selection for characteristics via click wheel

- Welding parameter – Display of the effective arc power for the simple calculation of energy per unit length

- Quick switching between MIG/MAG processes – The optimum for each welding task

- WPQR welding data assistant – Exact calculation of heat input and energy per unit length

- Language selection – Pre-configured languages for the user menu

Features

Titan XQR puls Fieldbus Interfaces

- Robot interfaces RINT X12/BUSINT X11

- Network connection with ewm Xnet 2.0 and built-in or external LAN or WiFi gateways

- Split box for changing systems with two welding torches

- 60 V sensor voltage for position search

- Water cooling set for Rob 5 − for retrofitting

M Drive 4 Rob 5 XR: The Ideal Wire Feeder for Automated Welding

The M Drive 4 Rob 5 XR is designed for both conventional and hollow wrist robotic systems. Featuring the eFeed system, it enables smooth wire inching and return. The rollers and flap are adjustable, allowing for left or right alignment to suit your setup. This flexibility ensures optimal performance for your automated welding needs.

Versatile Robot Welding Torches for Every Need

The Titan XQR Puls offers a wide selection of welding torches to meet your specific requirements. Choose from standard or hollow shaft models, with options for gas or water cooling, as well as push/pull or push/push configurations. You can even integrate a drum feed system.

To further enhance your setup, we offer welding torches with various neck bend angles, swan neck designs, collision sensors, wire feeders, and a variety of other accessories, providing a comprehensive solution for your robotic welding needs.

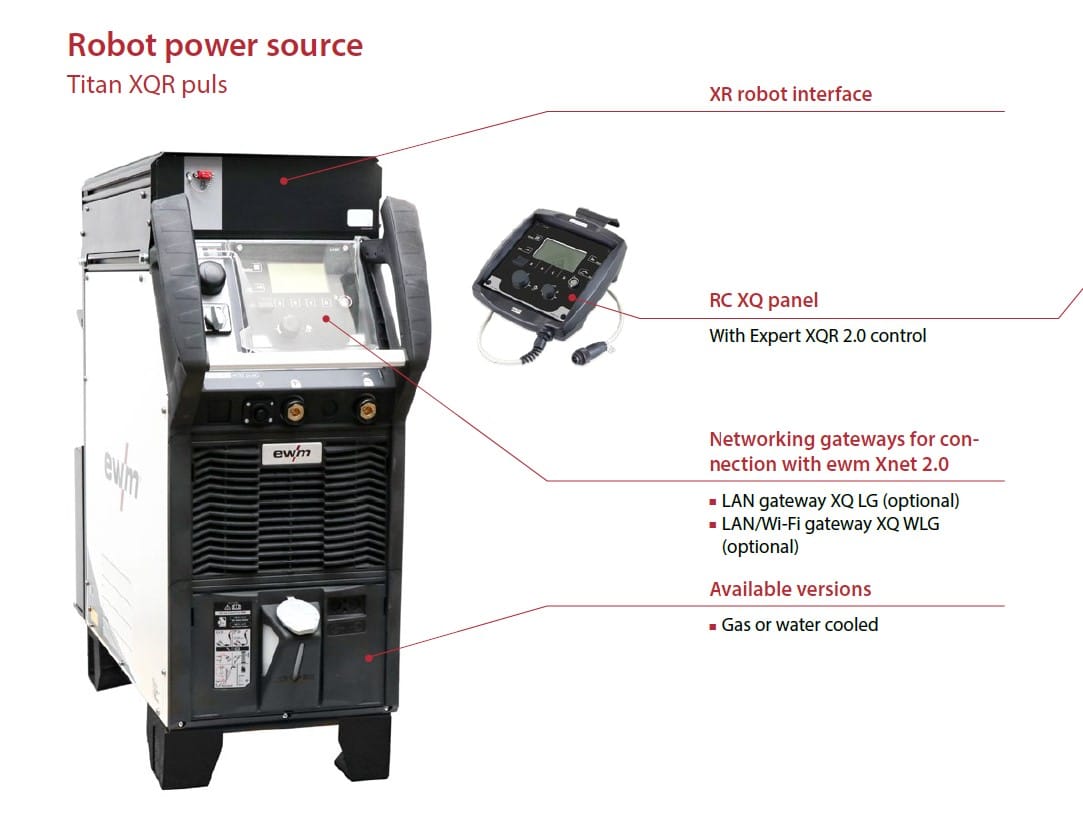

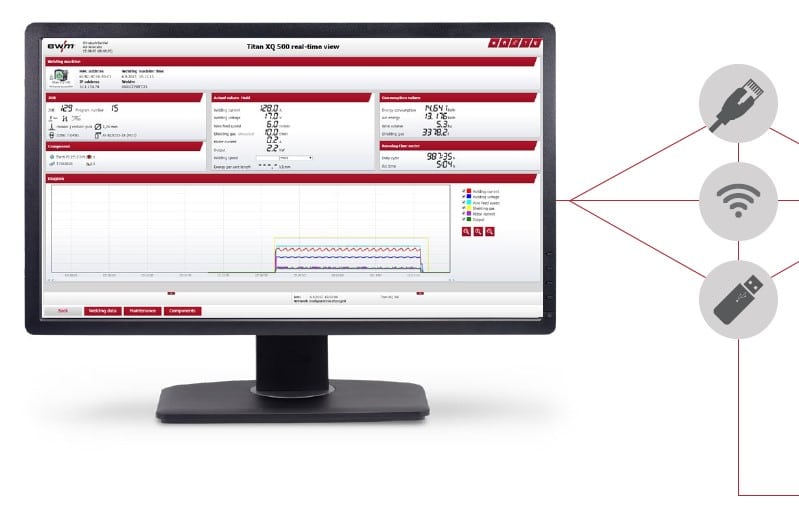

Welding 4.0: EWM Xnet 2.0 Welding Management System

Unlock the power of intelligent networking with EWM Xnet 2.0, the innovative welding management system designed to streamline data flow across your production chain. As Industry 4.0 becomes a reality in welding, ewm Xnet 2.0 brings future concepts like smart factories and digital transformation to life with ease.

The system enhances connectivity between people and products, driving efficiency, improving quality, reducing costs, and conserving resources. With real-time monitoring and transparent workflows from planning to production and final costing, you’ll always stay informed.

Whether you’re managing small operations or large-scale production, ewm Xnet 2.0 brings the benefits of Industry 4.0 to your welding processes.

For more information on this EWM product Click Here