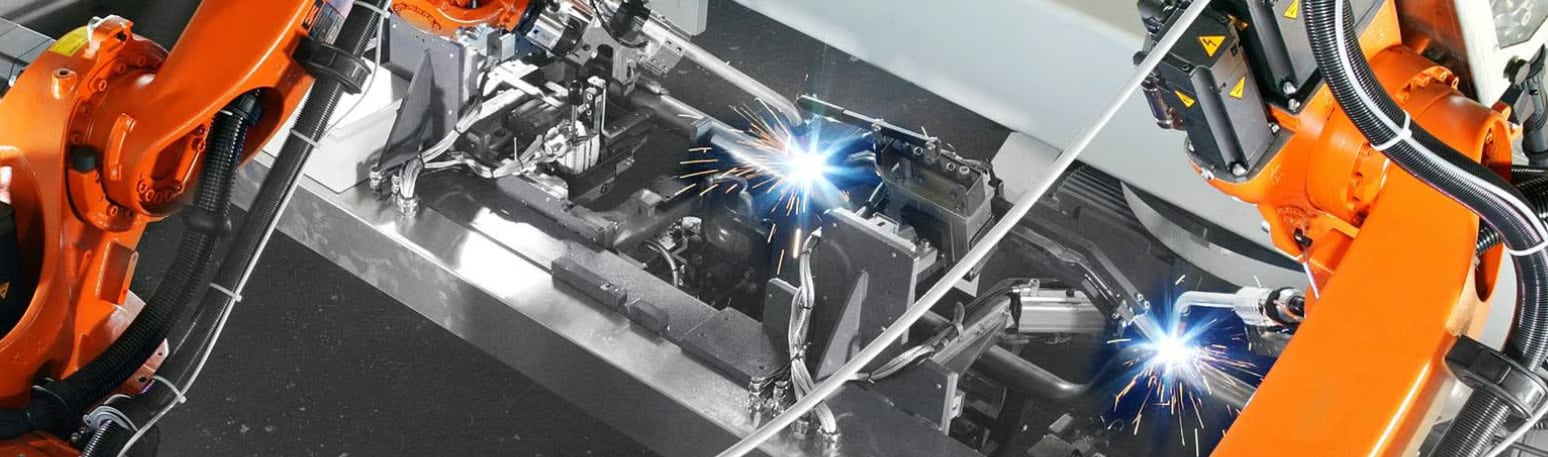

Dual Cell Welding Package – Kuka & Fronius Welder with Positioner

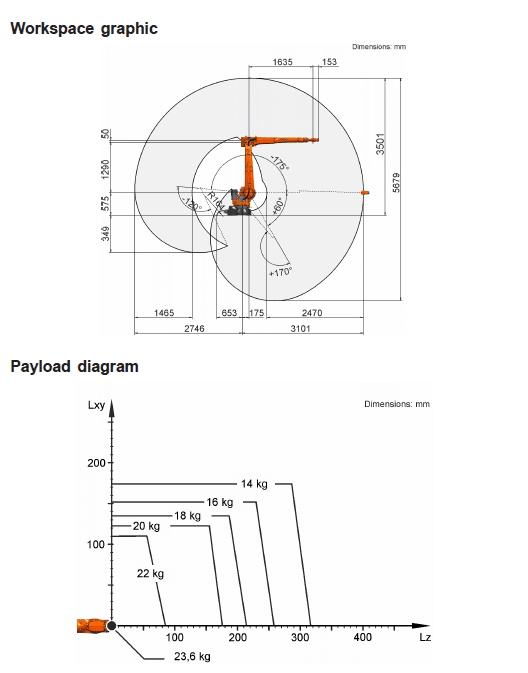

This package delivers a comprehensive, high-performance welding solution designed for efficiency, precision, and safety.

Complete Dual Call Welding Solution Package Includes:

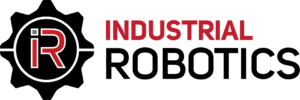

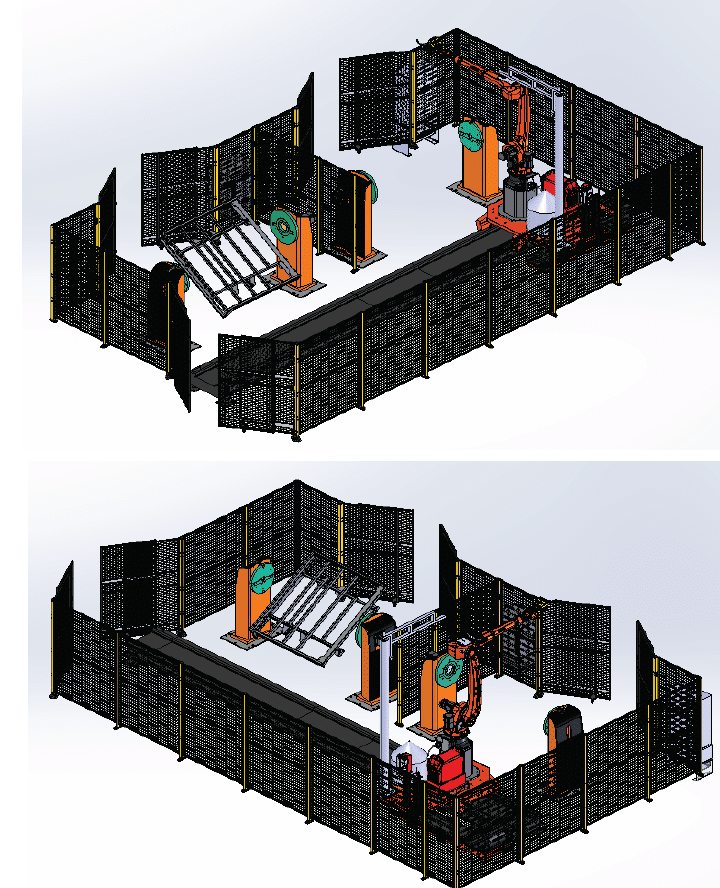

- KUKA KR 20 R3100 Robot: 3.1-meter reach, 20 kg payload.

- KUKA 9.5m Rail Dual: Extends operational range.

- Fronius TPS400i Welding Package: Integrated welding technology for the KUKA KR20.

- Fronius Torch Cleaning Station: Maintains torch quality.

- Rail Carriage Platform: Stable mounting for the welder.

- Leuze Light Curtains & Safety Hardware: Enhanced operator protection.

- Installation & Commissioning: Includes setup.

- Safety Fencing: With integrated welding eye protection.

- KUKA Positioners: Rotate and hold chassis parts securely during welding.

- Customizable Jigs: Adaptable for similar components with extendable/retractable features.

- Optional: BlueDragon Framework

Estimated development time for the solution is 3 months from order, including robot delivery time.

Cant find what you’re looking for?

Fill out our quote form instead.

Description

This package we recommend a collaborative robot with Fronius welding package that you can program through your RoboDK CAD software. This solution will allow you to enter the Industry 4.0 standards. It will provide you with substantial range of benefits for your company, including: reduce labor costs, increase productivity, increase safety, reduce RSI risks, improve product quality, reduce human error, streamline the process, reduce overall product cost, among other advantages.

Kuka Robot

Unmatched Performance with the KR20 R3100 Robot

This cutting-edge solution includes the KUKA KR20 R3100 robot, boasting a remarkable 3.1-meter reach and a 20 kg payload capacity. Designed for precision and reliability, it’s the perfect partner for complex welding applications.

Seamless Integration with KUKA ArcTech

Enhance productivity with preconfigured welding source profiles that guarantee compatibility with all common power sources. The KUKA ArcTech package simplifies integration and adapts to your needs, offering two flexible control modes:

- Job/Program Mode: Setpoint values via program numbers.

- Characteristic/Channel Mode: Setpoint values using multiple weld parameters.

The advanced robot controller ensures smooth communication with the power source through a field bus connection.

Precision Redefined with KUKA.TRACC TCP

Achieve perfect welds every time with KUKA.TRACC TCP. This innovative solution provides all the software and hardware required for automatic TCP (Tool Center Point) checking and calibration. Integrated into the KR C5 controller, it ensures that your robot maintains optimal accuracy and updates its TCP settings as needed during production.

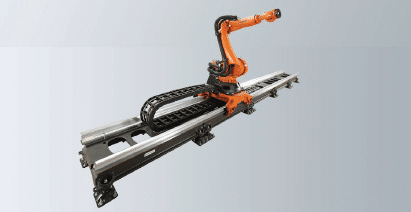

Extended Reach with KUKA Linear Rail (KL 4000)

Expand your system’s capabilities with the KL 4000 linear unit, a robust linear axis for payloads up to 4,000 kg. Key features include:

- Modular Design: Includes two 3,000 mm beam elements.

- Compact Carriage: Optimized motor and gear unit arrangement for space efficiency.

- High Performance: Repeatability of ± 0.02 mm, velocity of 1.89 m/s, and IP 65 protection rating.

- Flexible Installation: Floor or ceiling mounting options to suit your workspace.

Maximum Flexibility with KUKA Positioner KP1-HC

Take versatility to the next level with the KP1-HC single-axis positioner. Equipped with a horizontal rotational axis, this positioner offers:

- Exceptional Payload Options: Capacities of 500, 750, 1,000, 1,500, 2,000, or 4,000 kg.

- Customizable Tool Radii: Ranging from 800 to 1,470 mm for maximum system design flexibility.

- Robust Construction: Hollow shaft design for enhanced performance and durability.

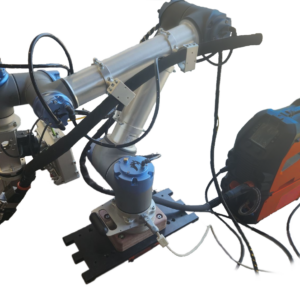

Fronius Welder Package

Cutting-Edge Components for Superior Performance

This advanced Fronius welding system is designed for efficiency, precision, and flexibility. The package includes:

- TPS 400i Power Source: Comes with a rear earth connection and podium for reliable, high-performance operation.

- Welding Processes: Features Pulse, Standard, and PMC processes for versatile applications.

- OPT/i Wire Sense Software: Ensures precise wire control and accuracy.

- Robotic Water Cooler CU1400 Pro: Includes a water flow sensor for optimal cooling and performance.

- TPSi Fieldbus Interface: Offers inside integration with ethernet or DeviceNet modules for seamless connectivity.

- Split Box 60i: Includes a 4m connection hosepack and mounting for streamlined operations.

- Air Blast and Gas Sensor Options: Enhances safety and operational control.

- WF25i Reel: Equipped with 1.2mm drive rollers, drum-mounted for efficient wire feeding.

- 10m Wire Supply Feed Hose: Designed for drum mounting and SB60i compatibility.

- MHP 500i Torch Hose Pack: With a 2.235m length for extended reach and precision.

- WF60i Robacta Drive CMT: Includes a 0.9mm steel basic kit for enhanced flexibility.

- WF60i Clamp with 36° Index Disk: Allows for precise positioning and stability.

- MTB 500i W Torch with Wear Parts: Offers exceptional durability and performance.

- Collision Box XL & Adaptor: For enhanced safety and reduced downtime.

- Earth Leads: Two 10m robotic earth leads for secure and efficient operation.

Dynamic Welding Configuration Tool

Tailor your welding processes with the versatile configuration tool, offering settings for any teaching method. Choose from various welding patterns to suit your needs:

- Linear Welding: Perfect for straightforward, continuous welds.

- Stitches: Ideal for intermittent welding applications.

- Zigzag Patterns: Provides extra strength and stability for certain joints.

- Tack Welding: Efficient for temporary fastening and pre-assembly.

Additionally, you can adjust critical parameters such as welding speed and start/end times for each path, ensuring optimal performance and precision.

RoboDK Software

RoboDK software is an ideal companion to convert CAD welding path to robot code. Plugin for AutoDesk Inventor is available to place the features as welds. Illustrator files can be directly imported to RoboDK, thus making the welding path in RoboDK. Start and stop welding on the path will be done with functions we will pre program.

For more information about RoboDK Software: Click Here

Optional Extra:

BlueDragon Framework – Click Here to learn more

For more information or to request a quote, please send us an enquiry. We’re here to help you achieve your goals with tailored business solutions designed for success.

Additional information

| Collaborative Robot | KUKA KR 20 R3100 Robot: 3.1-meter reach, 20 kg payload. |

|---|---|

| Welder Unit | Fronius TPS400i Welding Package: |

| Offline Programming | RoboDK |