Blue Dragon Welding Solution

Machine Vision Upgrade for Industrial Robotic Cells

Our Machine Vision Upgrade is a breakthrough in intelligent automation giving robotic cells the ability to see, understand, and adapt. Compatible with Universal Robots, KUKA, ABB, and other leading platforms, it scans parts in real time, automatically saves CAD files, and recognises features to trigger the right robotic operations.

Currently optimised for welding , this upgrade removes reliance on fixed jigs, reduces setup complexity, and delivers consistent results making advanced machine vision accessible, adaptable, and future-ready.

Cant find what you’re looking for?

Fill out our quote form instead.

Description

Blue Dragon Welding Solution

Engineered for Reach. Designed for Results.

The Blue Dragon Welding Solution is a breakthrough in intelligent automation — delivering precision welding, fabrication flexibility, and real-time production insights.

Unlike single-brand systems, Blue Dragon integrates seamlessly with any industrial or collaborative robotic arm. Paired with proven compatibility for leading welding units from Kemppi and Fronius, it gives manufacturers the freedom to choose the best hardware for their needs.

By removing the complexity, cost, and delays of third-party programming, Blue Dragon makes advanced robotic welding accessible, adaptable, and future-ready.

🔹 Why Choose Blue Dragon?

-

Flexible Production

Perfect for small runs, rapid prototyping, and variable orders without the need for complex reprogramming. -

No External Programmers Required

Avoid cost, risk, and downtime—your team can configure and run Blue Dragon without reliance on external specialists. -

Handles Real-World Variance

Automatically adjusts for part tolerances and deformations, preventing collisions with imperfect parts. -

Jig-Free Setup

Simply place parts on the work table — no custom fixtures required. -

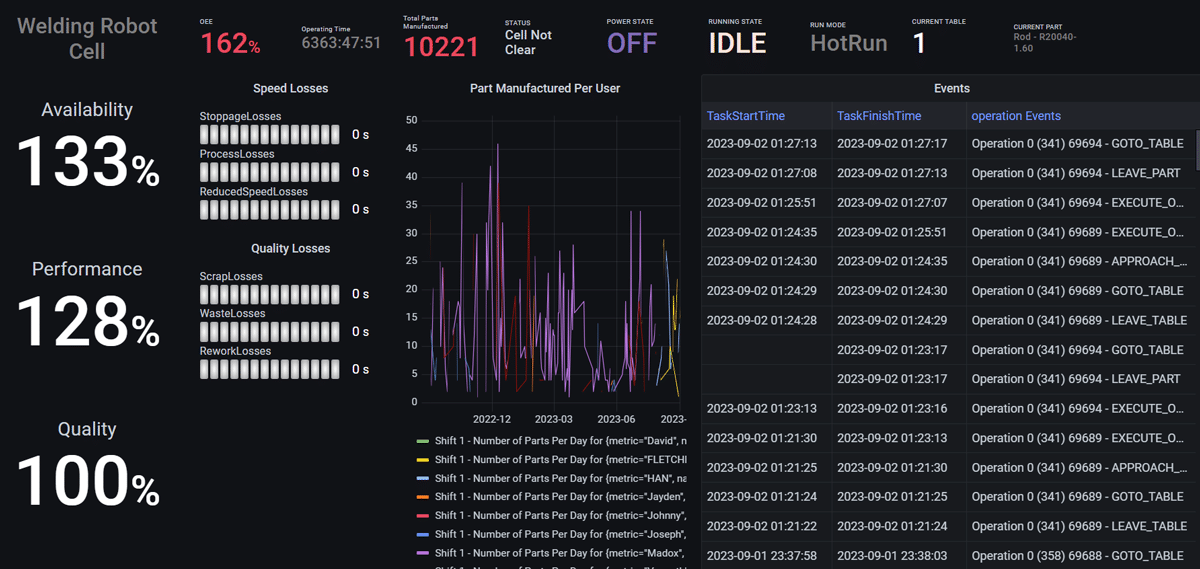

Smarter Data, Smarter Decisions

Business Intelligence Dashboard provides real-time production and quality statistics, accessible both locally and online. -

Fast ROI

Faster batch times + higher utilisation = rapid return on investment.

🌍 Unlimited Applications

Blue Dragon goes far beyond welding:

-

Fabrication, Machining & Finishing

-

Assembly & Dispensing

-

Quality Control & Analysis

-

Machine Tending & Inspection

Designed for full operation with lower-skilled staff, Blue Dragon also offers multiple training methods:

-

CAD-based programming

-

Hand teaching

-

Marker pen pathing

-

Scan-to-mesh from real parts

📊 Smarter Manufacturing with Real-Time Data

Blue Dragon empowers your factory with production intelligence at scale:

-

Local and cloud-based storage options

-

Real-time access to production metrics from anywhere

-

Generate factory-level reports and machine-specific statistics

-

Enhance traceability, compliance, and predictive maintenance

🔬 Proven Innovation

-

International Patent

PCT/AU2023/050277 – 3D Modelling and Robotic Tool System and Method -

Digital Twin Simulator

Test, refine, and validate processes virtually before execution.

📐 Technical Specifications

-

Accuracy: < 0.5 mm

-

No jig required

-

Scan-to-mesh and CAD-based programming

-

Process edges and surfaces with precision

-

Fits industrial and collaborative robot arms

-

Seamless integration with Kemppi & Fronius welding units

🚀 Automate Smarter with Blue Dragon

Blue Dragon isn’t just a welding solution — it’s a flexible, intelligent automation system that adapts to your production needs, scales with your growth, and delivers data-driven insights.

🤖 Robot-Agnostic by Design

Unlike single-brand solutions, Blue Dragon is agnostic — engineered to fit any industrial or collaborative robot arm. Whether you’re working with a UR cobot or another robotic platform, Blue Dragon integrates seamlessly to give you freedom of choice.

🛠️ Remote Digital Support

Our Remote Digital Support service ensures you’re never on your own. Whether you need troubleshooting, software updates, process optimization, or real-time guidance, our experts can connect securely to your system and provide instant assistance. This means faster issue resolution, reduced downtime, and lower service costs, keeping your production running smoothly without waiting for on-site visits.

📽️ See Blue Dragon in Action

Watch how Blue Dragon seamlessly integrates with a UR cobot arm and Kemppi welding units to deliver cleaner welds, smarter automation, and real-time production intelligence.

👉 Contact us today for any enquiries or to request a demo or quote! Contact Us