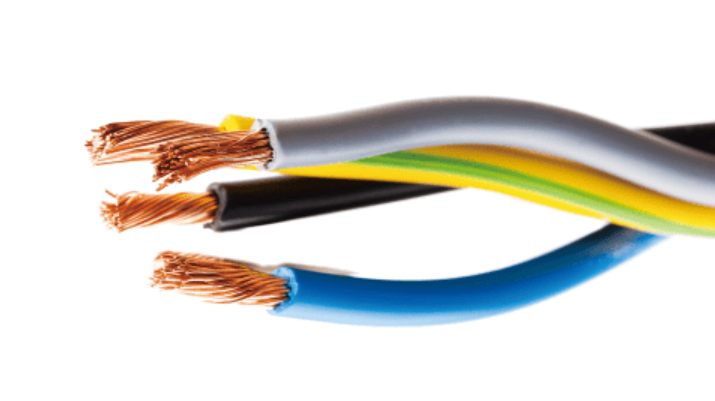

KURASENSE is a high-speed 3D vision sensor system developed by Kurabo Industries that equips robots with advanced visual intelligence. It recognises and handles flexible linear objects such as cables, connectors, FFCs/FPCs, optical fibers, and wire harnesses. Tasks that are notoriously difficult for conventional automation systems are managed with Kurasense.

Unlike traditional sensors, Kurasense doesn’t rely on rigid object shapes or pre-loaded CAD models. Its use of high-speed 3D scanning and a linear vector scanning algorithm allows it to dynamically detect twists, bends, and positional changes in real time, much like a human eye.

- Models & Mounting Options

- Kurasense-C100FX: Compact and ultra-high-resolution, mountable on robot hands; excels at detecting small and thin cables with high precision

- Kurasense-C100: Integrated sensor + controller unit, with a 0.1-second recognition cycle and up to 500 mm working distance

- Kurasense-A100: Lightweight, hand-mountable device for quick positioning and presence detection over 300 mm

- Precision & Performance

- XY resolution up to 0.03 mm—three times sharper than previous generations.

- Z-axis accuracy ±0.1 mm, a fivefold improvement

- Rapid recognition of flexible components (~0.1 seconds)

- Integration Ease

- Connects via a single LAN cable to a wide range of PLC and robotic systems. No complex CAD matching required

WIRE INSERTION

SMOOTH, PRECISE, AUTOMATED

Why It Matters

Flexible wires are inherently unpredictable. Bendy, twist-prone, and inconsistent. Kurasense tackles these challenges head-on by enabling robots to:

- Detect fine wire features, e.g. tip orientation, bend, twist, all down to sub-millimeter accuracy.

- Automate tasks such as wire harness assembly, soldering, connector insertion, and lead wire handling at high speed and quality.

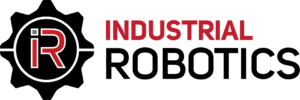

One of the standout applications is wire insertion into connectors, even for ultra-thin wires (down to 0.5 mm in diameter!). Kurasense’s rapid, accurate vision allows robots to:

- Accurately pick a single wire from a bundle.

- Recognize its orientation and direct a terminal crimping or soldering operation.

- Insert it reliably into connectors, with optional in-line inspection to reject defects.

Real-World Automation Packages

Learn more about comprehensive robotic packages tailored for industrial needs. Enquire today about the:

- Kurassem-WH (Wire Harness): Fetches a cable from a bundle, crimps, and inserts it into a connector—typically within 5–10 seconds per piece. Customizable for soldering and testing.

- Kurassem-C Series (Connector Insertion): Designed for FFC/FPC flat cables and square connectors—robots grasp and insert connectors into boards with precise alignment in about 14 seconds.

These packages deliver fast, flexible automation while maintaining customization and production speed.

Quick Recap

| Feature | Benefit |

|---|---|

| High-speed 3D vision | Rapid recognition of bendy, flexible materials |

| Sub-millimeter precision | Reliable handling of ultra-thin wires and cables |

| Robot-hand mountable | Compact integration, including on robot arms |

| No CAD needed | Saves setup time and increases flexibility |

| Plug-and-play setup | Seamless integration with varied robotic systems |

| Complete automation kits | End-to-end solutions from wire pick-up to inspection |

| Adaptive robot synergy | Safe, precise human–robot collaboration |

Kurasense is a leap forward in automating dexterous tasks that used to be only for human fingers. Those bendy, flexible wires can now be managed with automation. Whether integrated into wire harness assembly lines or paired with adaptive robots for ultra-precise tasks let’s open up the new horizons in electronics, automotive, and beyond.

If your production line involves wire insertion, flexible cabling, or connector assembly (especially in high-mix, high-precision environments), then Kurasense could be very well be your key to unlocking speed, quality, and reliability.

📩 Contact Industrial Robotics today to explore how we can support your factory with automation solutions – no matter the size! Click Here!

Phone 07 34173473